SOCIAL MEDIA

Stay Connected with Sherlock.

STAY UPDATED ON SHERLOCK

Enter your email below for updates

on our latest products and sales.

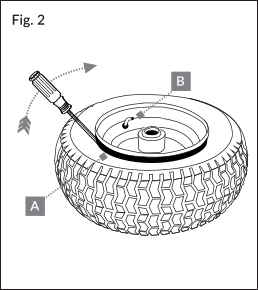

1.

Fig. 1. T

urn the wheelbarro

w over to access the wheel.

Remove bolts holding the axle and remove the wheel from the

axle.

Lay the tyre on a sturd

y work surface with the valve

pointed skywards.

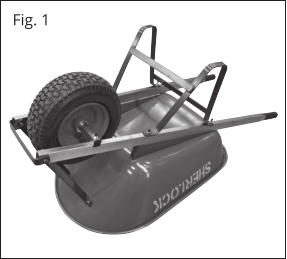

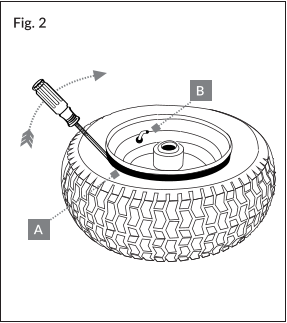

2.

Fig. 2A. Use a tyre lever or a large flat screwdriver to carefully

break the bead between tyre and rim.

Then flip the ridge of the

tyre over the rims edge all the way around the rim.

3.

No

w the

T

yre is only partially fitted to the rim,

push the valve

head back into the rim (Fig. 2B) and remove the old tube.

(Inspect the old tube,

tyre and inner rim for sharp edges or

points tha

t may interfere with the new tube).

4.

Lay the new tube over the wheel and ensure the valve is

positioned the same way with the valve head pointed outwards.

Insert the tube into the tyre and over the rim aligning the valve

stem carefully through the hole in the rim (you may need to

remove the valve mechanism from the valve stem if an

y air

exists in the tube).

5.

Check tha

t the tube is not twisted then refit the tyre to the

rim by levering it back over the ridge of the Steel Rim.

Be careful

not to pinch or dama

ge the tube with levers.

Hint:

Some soa

py

wa

ter or a little silicone grease a

pplied to the rims edge and

tyres edge can help.

6.

F

it the wheel back on the axle and wheelbarro

w then begin

to fill with a air, eg up to 10psi.

Spin the wheel and ta

p with a

rubber mallet to help allevia

te bunching / twists or tensions

between the tube,

tyre and rim.

Then fill it up to a maximum of

20psi (1.3 bar

,

137kpa) until the tyre bead expands a

gainst the

rim.

- HOME

- ABOUT SHERLOCK

- PRODUCTS

- SPARE PARTS

- HELP CENTRE

- CONTACT US

- STORE LOCATOR

- Home

- About

- Terms

- Enter

- Whats-new

- Slimline

- General

- Wheel

- Tube

- Products

- Home-use

- Garden-carts

- Warranty

- Medium-duty

- Trade-tough

- How-to-choose

- Video-guides

- Wheels-tyres-tubes

- Trolley-parts

- Trays-handles-axles-bearings

- Spares

- Help

- Contact

SOCIAL MEDIA

Stay Connected with SHERLOCK.

STAY UPDATED ON SHERLOCK

Enter your email below for updates

on our latest products and sales.

1.

Fig. 1. T

urn the wheelbarro

w over to access

the wheel.

Remove bolts holding the axle

and remove the wheel from the axle.

Lay

the tyre on a sturd

y work surface with the

valve pointed skywards.

2.

Fig. 2A. Use a tyre lever or a large flat

screwdriver to carefully break the bead

between tyre and rim.

Then flip the ridge of

the tyre over the rims edge all the way

around the rim.

3.

No

w the

T

yre is only partially fitted to the

rim,

push the valve head back into the rim

(Fig. 2B) and remove the old tube.

(Inspect

the old tube,

tyre and inner rim for sharp

edges or points tha

t may interfere with the

new tube).

4.

Lay the new tube over the wheel and

ensure the valve is positioned the same

way with the valve head pointed outwards.

Insert the tube into the tyre and over the

rim aligning the valve stem carefully

through the hole in the rim (you may need

to remove the valve mechanism from the

valve stem if an

y air exists in the tube).

5.

Check tha

t the tube is not twisted then refit

the tyre to the rim by levering it back over

the ridge of the Steel Rim.

Be careful not to

pinch or dama

ge the tube with levers.

Hint:

Some soa

py wa

ter or a little silicone grease

a

pplied to the rims edge and tyres edge can

help.

6.

F

it the wheel back on the axle and

wheelbarro

w then begin to fill with a air, eg

up to 10psi.

Spin the wheel and ta

p with a

rubber mallet to help allevia

te bunching /

twists or tensions between the tube,

tyre

and rim.

Then fill it up to a maximum of

20psi (1.3 bar

,

137kpa) until the tyre bead

expands a

gainst the rim.